In a world where rapid technological evolution intersects with a pressing need for environmental stewardship, Industry 4.0 emerges as the superhero of modern times. It’s not just a futuristic concept or a buzzword thrown around in tech conferences; it’s a revolutionary movement. Envision a universe where machines whisper secrets to one another, optimizing production, while also leaving a minimal carbon footprint. Where artificial intelligence not only boosts productivity but ensures a tree remains unharmed and a stream flows unpolluted. Welcome to the fascinating juncture of Industry 4.0 and sustainability, a confluence that promises to redefine our tomorrow. Dive in, as we explore this transformative journey that marries efficiency with responsibility.

Industry 4.0, a transformative paradigm in manufacturing and technology, has redefined the way industries operate. It encompasses a fusion of cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI), and automation to enhance productivity and efficiency. However, in this era of heightened environmental awareness, Industry 4.0 also plays a pivotal role in fostering sustainability.

By optimizing resource utilization, reducing waste, and enabling smarter decision-making, it contributes to eco-conscious manufacturing. This synergy between technological advancement and sustainability is not only imperative for a greener planet but also essential for businesses seeking long-term competitiveness and resilience in a rapidly evolving global landscape. Read ahead to learn more about how Industry 4.0 is helping to embrace sustainability and improve productivity across industries.

Industry 4.0 and Sustainability

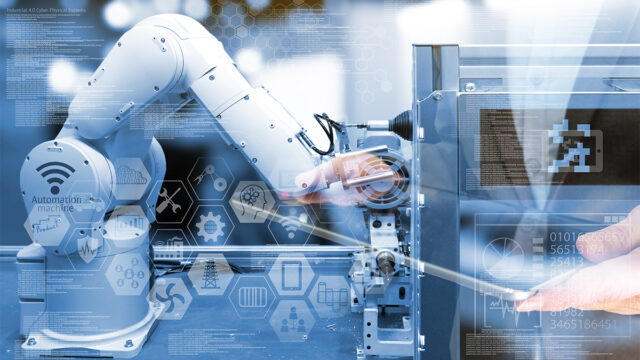

Industry 4.0 and sustainability represent two interconnected paradigms that are reshaping the world of manufacturing and business. Industry 4.0 is characterized by the integration of digital technologies, such as the Internet of Things (IoT), artificial intelligence, and automation, into industrial processes. It aims to enhance productivity, efficiency, and competitiveness across various industries.

Sustainability, on the other hand, is a global imperative driven by the growing awareness of environmental and social issues. It calls for responsible resource management, reduced environmental impact, and the equitable treatment of communities. Achieving sustainability involves addressing key challenges like climate change, resource depletion, and social inequality.

The intersection of Industry 4.0 and sustainability is where innovation meets responsibility. Industry 4.0 technologies offer powerful tools to optimize resource utilization, reduce waste, and minimize the environmental footprint of manufacturing processes. IoT sensors can monitor energy consumption and emissions, while AI can optimise supply chains for efficiency and reduced environmental impact. Smart manufacturing processes enable predictive maintenance, reducing downtime and waste.

Moreover, Industry 4.0 enables the development of sustainable products. Design processes can be optimized using digital twin simulations, ensuring products are eco-friendly and meet regulatory requirements. Additive manufacturing, another Industry 4.0 technology, allows for resource-efficient production and customisation.

Sustainability is not solely about environmental concerns; it also encompasses social responsibility. Industry 4.0 technologies can improve working conditions, safety, and employee well-being through the automation of repetitive tasks and advanced safety measures.

How is it Improving Productivity?

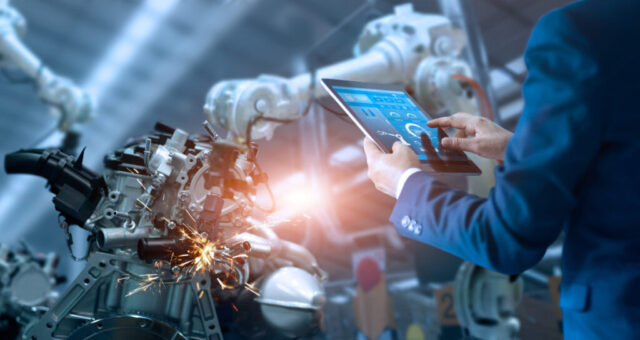

Industry 4.0 is revolutionizing productivity across various sectors by leveraging advanced digital technologies and automation in several key ways.

- Efficient Data Utilization: Industry 4.0 harnesses the power of big data and analytics. Machines, as well as sensors, collect vast amounts of data, providing valuable insights into production processes. Real-time data analysis enables proactive decision-making, reducing downtime, optimizing resource allocation, and improving overall efficiency.

- Predictive Maintenance: Through IoT-connected sensors and AI algorithms, Industry 4.0 predicts equipment failures before they occur. This allows for scheduled maintenance rather than reactive repairs, minimizing unplanned downtime and boosting productivity.

- Automation and Robotics: Automation is a cornerstone of Industry 4.0. Robots and autonomous systems can handle repetitive and labor-intensive tasks with precision and consistency, freeing up human workers for more complex and creative roles.

- Customisation and Flexibility: Industry 4.0 facilitates mass customisation. Smart manufacturing processes can quickly reconfigure production lines to adapt to changing customer demands, reducing lead times and waste.

- Supply Chain Optimisation: AI-driven algorithms optimize supply chains by predicting demand fluctuations, ensuring just-in-time deliveries, and minimizing excess inventory. This reduces costs and enhances production efficiency.

- Quality Control: Advanced sensors and AI-based quality control systems can detect defects and anomalies in real-time, ensuring that products meet high-quality standards and reduce waste.

- Human-Machine Collaboration: Augmented reality (AR) and virtual reality (VR) technologies enable improved collaboration between humans and machines, enhancing worker productivity and efficiency.

Industry 4.0 is the Way to Go!

Embrace Industry 4.0! By integrating cutting-edge technologies like IoT, AI, and automation, you can streamline processes, boost productivity, and gain a competitive edge. Predictive maintenance, real-time data analytics, and agile production will transform your operations. Don’t wait – harness the power of Industry 4.0 to scale up your organization and stay ahead in today’s dynamic business landscape.

The Environmental Benefits of Industry 4.0

The greening potential of Industry 4.0 cannot be underestimated. Beyond boosting efficiency, these technologies have a direct positive impact on the environment.

Reduced Energy Consumption: Many Industry 4.0 tools, like IoT-enabled devices and AI, can make real-time adjustments to energy consumption. For example, in factories, AI algorithms can predict periods of high and low demand, adjusting machinery usage accordingly. This leads to significant energy savings and reduced carbon footprints.

Circular Economy Facilitation: Industry 4.0 encourages the shift towards a circular economy – a model that focuses on reusing, sharing, repairing, refurbishing, remanufacturing, and recycling to create a closed-loop system. With better tracking and data analytics, companies can trace materials and ensure they are recycled or reused, rather than discarded.

Smarter Transportation: Advanced analytics can optimize transportation routes for product delivery, reducing carbon emissions from unnecessary mileage and ensuring efficient fuel usage.

Strengthening Business Ethics and Sustainability

When companies adopt the principles of Industry 4.0, they don’t just modernize their operations; they are also making an ethical statement.

Transparency and Accountability: Advanced sensors and tracking methods offer a newfound level of transparency in operations. Companies can provide real-time insights to stakeholders about their sustainability initiatives, ensuring that promises are kept.

Stakeholder Engagement: Industry 4.0 allows businesses to actively engage with their stakeholders, including customers, through digital channels. This can enhance trust and establish stronger brand loyalty among environmentally-conscious consumers.

Future-Proofing with Industry 4.0

Preparing for the future is essential for any business. As environmental regulations become stricter and consumer demand for sustainable products increases, Industry 4.0 serves as a bridge to this future.

Adapting to Regulatory Changes: As governments worldwide tighten environmental regulations, companies equipped with Industry 4.0 technologies will find it easier to adapt. Real-time monitoring ensures compliance and provides the data necessary for reporting and adjustments.

Meeting Consumer Expectations: Modern consumers are increasingly eco-conscious, preferring sustainable products over others. With Industry 4.0, businesses can ensure that their offerings meet these expectations, from resource-efficient production to recyclable packaging.

In conclusion, Industry 4.0 is not just a buzzword or the latest trend; it’s a comprehensive approach that aligns technological advancements with sustainability goals. Businesses that adopt this model are not only investing in efficiency and productivity but are also contributing to a sustainable and prosperous future.