The production process is the foundation of every technological process. An important link to every production process is human. In the organized process of work is man exposed to dangers and harms on a daily basis. Dangers at work we consider everything that can endanger the life and health of employees. Safety at work is everything that needs to be done to create a safe and healthy work environment. Conditions for safe work are realized in the case when the means of work, man, and the working environment meet the requirements that comply with the rules of safety at work, and those as such permanently ensure the proper functioning of the work process.

Production management is also a scientific discipline, which studies the phenomena in production systems, which affect the formation of relationships between people and means of work in the process of transforming the object of work into a finished product or new value, which the buyer is willing to pay a competitive price. Workplace hazards are those facts and conditions which, under certain conditions, may endanger the life and health of workers and may cause injuries at work. Hazards can be mechanical, electric hazards, fire, and explosion hazards, and thermal hazards (hot and/or cold substances and objects).

There are many different dangers in the human workspace. These hazards can cause injuries or adversely affect the body and the working capacity of workers. Unwanted consequences occur if the relationship between man and his environment is disturbed. The work environment consists of the space in which a person works and the means with which he works. A person spends at least one-third of his life at work, so the relationship between the person and the work environment should be taken into account. The working space and the working environment are standardized and are taken into account when designing work facilities.

The key to an accident prevention solution lies in the human-work environment rIt is also important to have your staff trained to know how to respond to medical emergencies in the workplaces. You can click here to learn how BLS courses, First Aid Training, and CPR courses can help make your workplace safer.

elationship.

There is no safe work in an unsuitable environment. The most important thing is to know that we can influence both men and the work environment. There are several ways in which each production can take more account of the safety of its workers.

1. Risk assessment

Risk assessment is a procedure that determines the level of danger, harmfulness, and effort in terms of injuries at work, occupational diseases, work-related diseases, and disturbances in the work process that could cause harmful consequences for the safety and health of workers. The employer is obliged to have a risk assessment made in written or electronic form, which must at all times correspond to the existing risks at work and in connection with work and which is available to the worker at the place of work.

Even when you think you have taken all the necessary measures to protect your workers, an unforeseen situation occurs in which the worker is injured. Stumbling, slipping, and falling on stairs are considered to be the most common cause of injuries. For this reason, it is necessary to pay special attention to this segment, which can be achieved with antifatigue mats. In this way, slipping is effectively prevented and workers can do their job unhindered without thinking about injury. You can go to this website to find more about it.

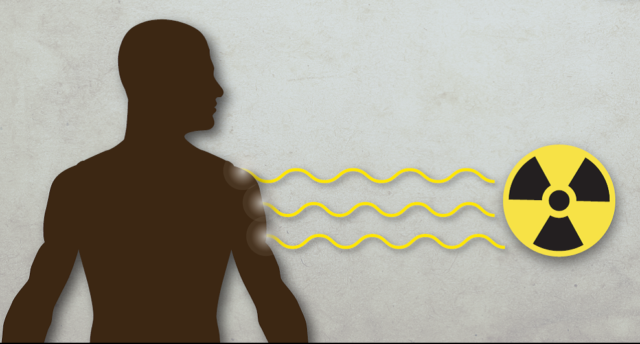

2. Radiation

Harmful radiation to which an employee may be exposed during work may be ionizing radiation when the radiation source is certain radioactive elements and devices that produce radiation. Laser radiation, which is a large amount of energy, can also be particularly harmful directed at a small area can cause mild skin damage redness to deep burns, and on the eyes (cornea, retina, and lens) severe damage. Chemical hazards are also present, and for this reason, it is necessary that workers have adequate protective equipment.

3. Occupational injury and occupational disease

An accident at work is considered to be any unwanted or unplanned event that could have occurred cause injury to workers or material losses, but by coincidence, to such detrimental, the consequence did not come. One of the key causes of an accident is a malfunction of the means of work or improper handling. The key to accident prevention lies in the human-work environment relationship. In inappropriate, there is no safe work in the environment. The most important thing is to know that we can affect both the person and the work environment to influence.

4. Internal control

This term is defined as internal supervision over the application of occupational safety rules and encouraging and advising the employer and his authorized representatives to eliminate deficiencies in occupational safety identified by internal supervision. Effective internal control in the field of occupational safety cannot solve all the company’s problems. However, ineffective internal oversight or lack of it can cause serious problems for the company.

5. Protection measures

Occupational safety measures include all technical, health, educational and upbringing, legal, psychological, social, promotional, and similar measures which, in accordance with existing regulations, rules of the profession, scientific and professional knowledge, achieve the basic objectives of occupational safety.

Occupational safety measures are divided into previous occupational safety measures, current occupational safety measures, and curative occupational safety measures.

Current safety measures at work are all those measures that are applied during production, and in accordance with the nature of the technological process and in each of its phases until the finalization of production.

Every company, organization, or larger industry strives to achieve maximizing profits, production of quality products or services, and economic business. To achieve this, various methods are used tools in all organizational units. As mentioned earlier the most important feature of this period is automation. With the advent of new more advanced machines, the time period of process execution was shortened and some work processes have merged into one continuous line and are thus reduced the need for human strength or the door to investment opportunities opens up labor into other fields of interest.

Final thoughts

In case of injuries at work, it is necessary to determine the reasons for the occurrence, omissions, and measures how the same would not happen again. It is necessary to record all injuries at work and occupational diseases as well on the basis of these data, make an analysis of injuries at work and on the basis of the obtained results of the analysis plan and take measures and activities to improve safety at work.