Enter the compelling world of fracture analysis, where the breaking point of materials isn’t just a point of failure, but a valuable datum in a broad spectrum of industries. Understanding these phenomena is not only intriguing but also indispensable in fields ranging from construction and transportation to defense and aerospace.

As we delve into the nitty-gritty of fracture analysis, we’ll unpack its significance, learn about the sophisticated tools employed, such as impact testing machines, and explore the factors influencing fracture behavior.

Understanding Breaking Points

A ‘breaking point,’ in the realm of materials science, denotes the moment at which an object or material is strained to its limit, leading to breakage or irreversible damage. As unassuming as it may sound, this point can speak volumes about a material’s resilience, sturdiness, and suitability for various applications. The breaking point is also an indicator of safety levels in numerous industries – a primary reason why it commands significant attention from engineers and researchers alike.

These are governed by the fundamental laws of physics, intricately woven into the atomic and molecular structure of materials. Stress and strain interactions play out differently in diverse materials, leading to a wide array of breaking points. These materialistic symphonies and their dynamic interplay define the lifecycle of structures, machines, and myriad objects that we rely on in our daily lives.

Significance of Fracture Analysis

Fracture analysis, in simple terms, is the systematic investigation into why a material or an object fails under stress. It is the detective of material science, uncovering the underlying reasons behind a component’s failure. The outcomes of these analyses play a pivotal role in enhancing the design, durability, and safety of objects, and hence, in the overall progress of industries.

Delving deeper, fracture analysis transcends the mundane ‘why’ and ‘how’ of failure and delves into the realm of prevention and improvement. By determining the conditions leading to fractures, scientists can develop improved, more resistant materials, and engineers can design structures and systems less likely to fail. Thus, it serves as the crystal ball that guides the future of material science and engineering.

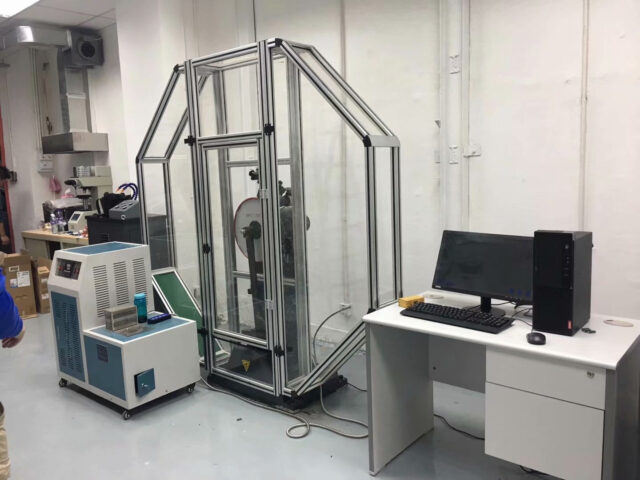

Overview of Impact Testing Machines

Impact testing machines are the workhorses that power fracture analysis. They apply known stresses to test samples, causing them to break and allowing scientists to analyze the resultant fractures. These machines have revolutionized the field of material testing, providing precise, repeatable results that fuel innovative designs and safer structures.

At their core, impact testing machines are about control. They precisely control the magnitude and direction of the stress applied, the temperature of the test sample, and the recording of the process. This intricate choreography of controlled variables enables the extraction of valuable data that form the backbone of detailed analysis, making these machines an indispensable part of the material testing landscape.

Types of Impact Testing Machines

From the massive machines used for testing steel girders to the miniature devices used for thin film analysis, the world of impact testing machines is as diverse as it is fascinating. Charpy and Izod testers are two prominent examples. These machines specialize in impact testing and have helped define safety standards across various industries.

On the other hand, dynamic tear testing machines and drop weight testers offer a different perspective. These machines subject test samples to extreme impacts or sudden forces, simulating real-world conditions like crashes or falls. This versatility not only broadens the scope of fracture analysis but also allows for more realistic and application-specific testing.

Principles of Impact Testing

At the heart of impact testing lies a simple yet profound principle: subjecting a material to known stress to observe its fracture behavior. It’s akin to pushing a swing – the force applied (the push) causes the swing (the material) to respond in a specific manner. This relationship between stress and response forms the core principle of impact testing.

The principle also involves controlling variables such as temperature and strain rate. By doing so, it allows scientists to replicate various environmental conditions and understand how they affect a material’s fracture behavior. Thus, impact testing isn’t just about causing fractures; it’s about recreating the myriad scenarios that a material might face in its lifetime.

Importance of Fracture Analysis in Impact Testing

Fracture analysis and impact testing are two sides of the same coin. Without the insights provided by it, impact testing would be a brute-force exercise. Conversely, without impact testing, it would lack the empirical data it needs to draw accurate conclusions.

The significance of impact testing becomes more evident when we consider the outcomes it offers. By analyzing the patterns, material scientists can not only identify the flaws and stressors that caused the fracture but also predict the material’s behavior under similar future stresses. This predictive ability is what makes it so integral to impact testing and, by extension, to material science.

Factors Affecting Fracture Behavior

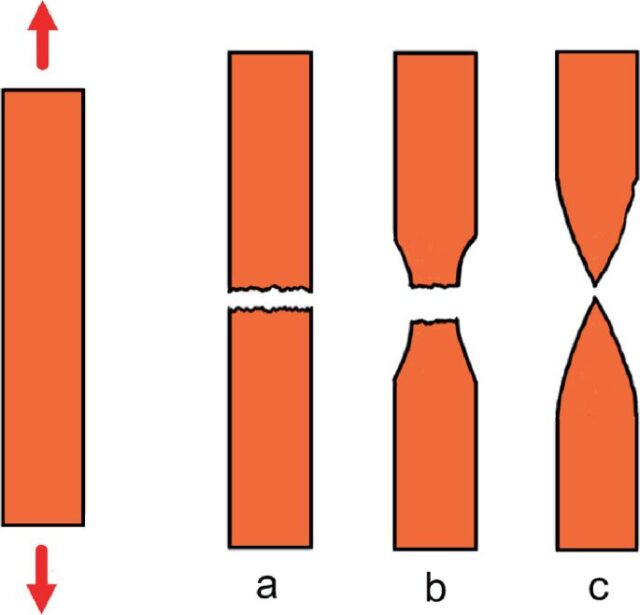

Fracture behavior isn’t an isolated phenomenon. It’s influenced by a multitude of factors, such as material composition, loading conditions, and environmental variables. For instance, the same piece of glass will shatter differently when struck with a hammer versus when subjected to slow, increasing pressure.

Yet, the effect of these factors extends beyond the material’s inherent properties. External conditions like temperature, humidity, and the presence of corrosive elements can significantly alter fracture behavior. For instance, metals tend to become more brittle at low temperatures, a property that could lead to catastrophic failures if not accounted for. Thus, understanding these factors is paramount for accurate fracture analysis and safe material use.

Interpreting Patterns

Fracture patterns are like fingerprints, unique to each break, but rich in information. They tell a story of stress and strain, of resistance and failure. Interpreting these patterns is as much an art as it is a science. It involves understanding the interactions between material properties, loading conditions, and environmental factors that led to the fracture.

While interpreting the patterns can be complex, it holds immense value. By “reading” these patterns, scientists can reverse-engineer the conditions leading to the fracture, helping to avoid similar failures in the future. Moreover, it opens up avenues for material innovation, driving the quest for more robust, resilient, and sustainable materials.

Summary

The journey through the captivating world of fracture analysis and impact testing machines is one marked by an intricate interplay of physics, material science, and engineering. It offers us insights into the breaking points of materials, allowing us to design safer structures, innovate more resilient materials, and prevent catastrophic failures. As we continue to unravel the mysteries of fracture behavior, we’ll move one step closer to a safer, more durable, and innovative future. The importance of understanding and harnessing these phenomena cannot be overstated, underscoring the importance of the ‘breaking point’ in our world.